XURUI

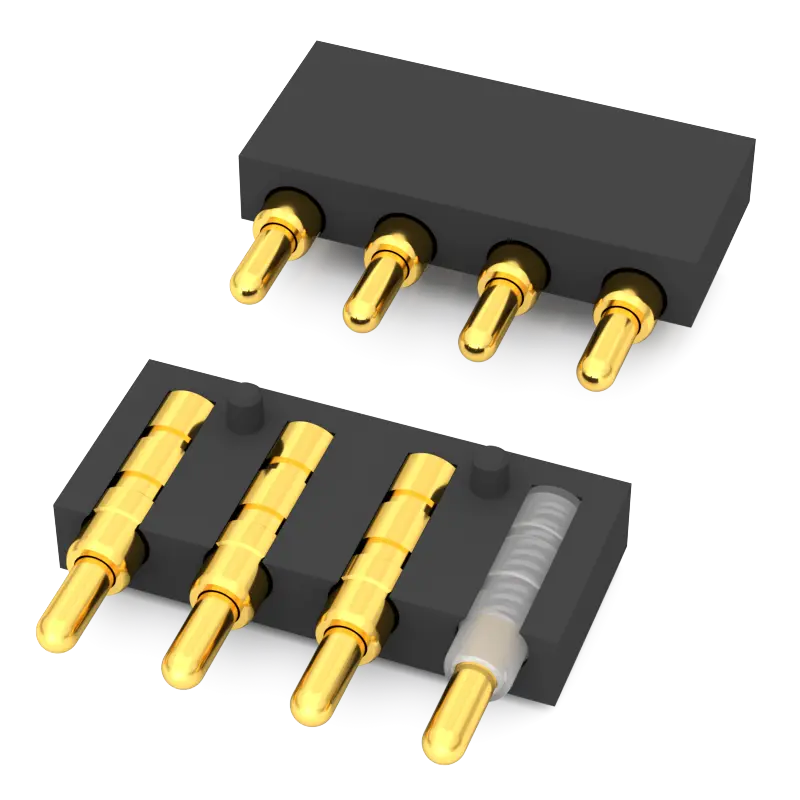

SMD Side Contact Pogo Pin Connector

(SMD side contact spring loaded connector)

SMD side contact pogo pin connector also known as smd side contact spring loaded connectors, smd side contact magnetic pogo pin connector, and through hole mount smd side contact spring connector, serve the core function of conducting electricity or signals.

I Innovative design: Slope Structure Design, More Stable Contact, Lower Resistance

I Installation method: SMT surface mount (SMD) reflow soldering

I Contact Resistance: 30 milliohms Max.

I Rated Current: 2A~15A (Continuous Current)

I Rated Voltage: 36V AC/DC

I Durability: 10,000~100,000 Times (Reciprocating Motion Lifespan)

I Operating Temperature: -40°C to +120°C (Continuous Temperature)

I Salt Spray Resistance 96 Hours Corrosion Test

I High-Precision Mold And Parts Processing

I A variety of standards are available, and samples will be sent out as soon as the same day.

I Provide Customized Services

I Comply With EU RoHS And Reach Standards

xurui

SMD Side Contact Pogo Pin Connector Product Details

What is a smd side contact pogo pin connectors

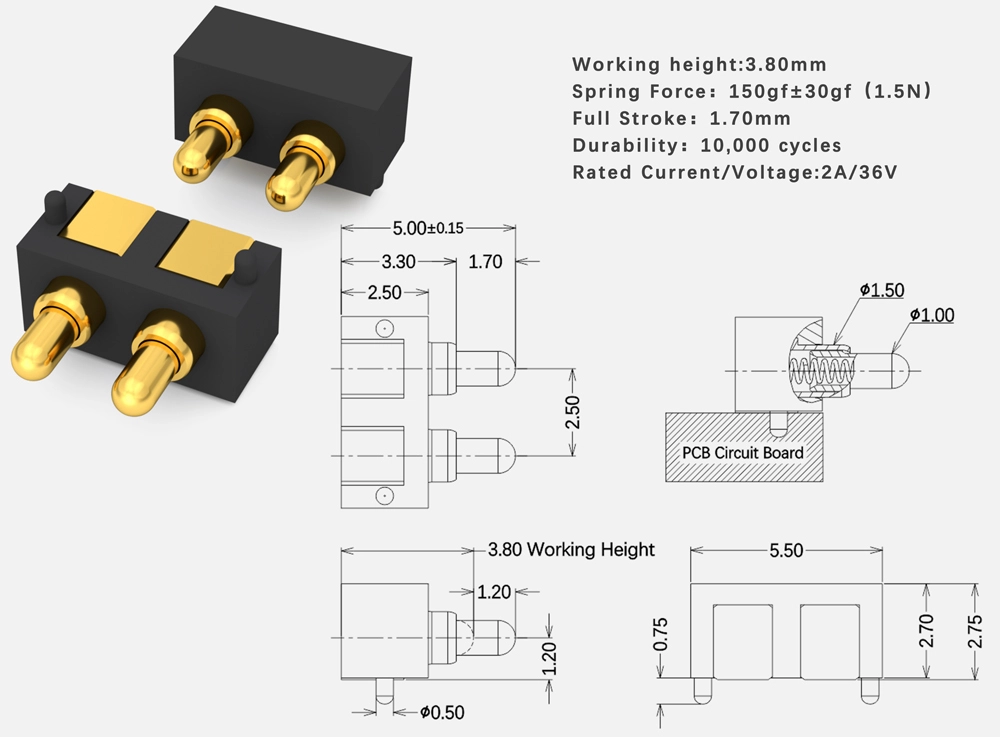

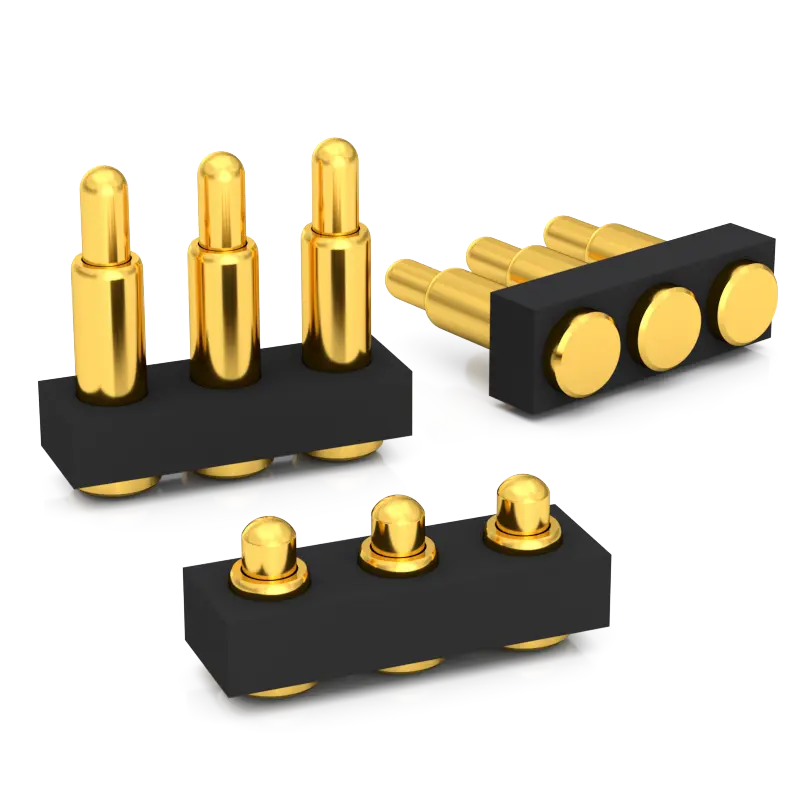

The SMD Side Contact Pogo Pin Connector, also known as the Right Angle Pogo Pin Connector, Pogo Pin Connector, and SMD Side Contact Spring-loaded Connector, primarily serves to connect for conductivity or signal transmission.

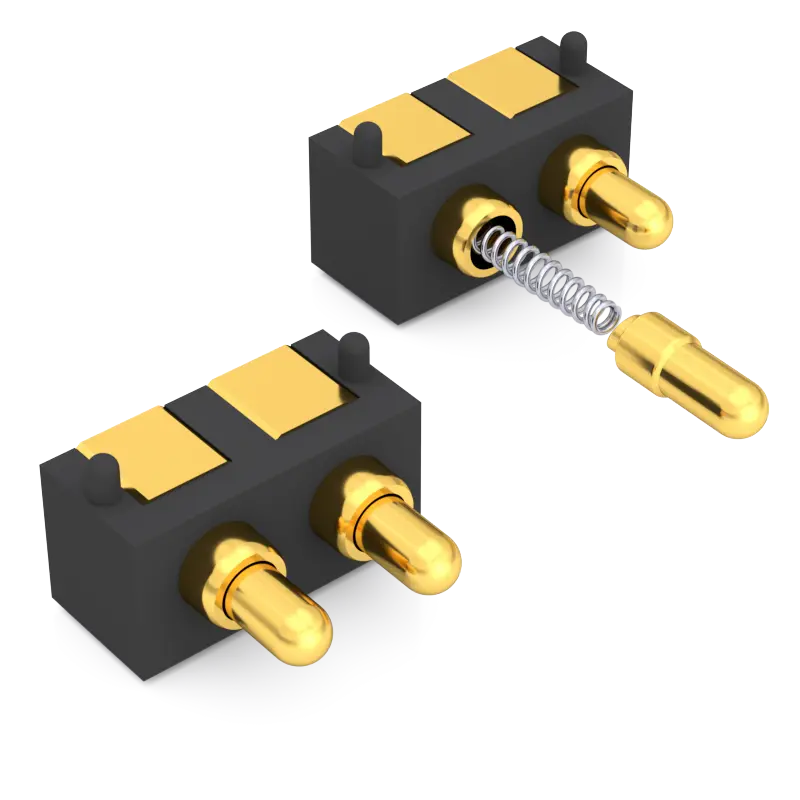

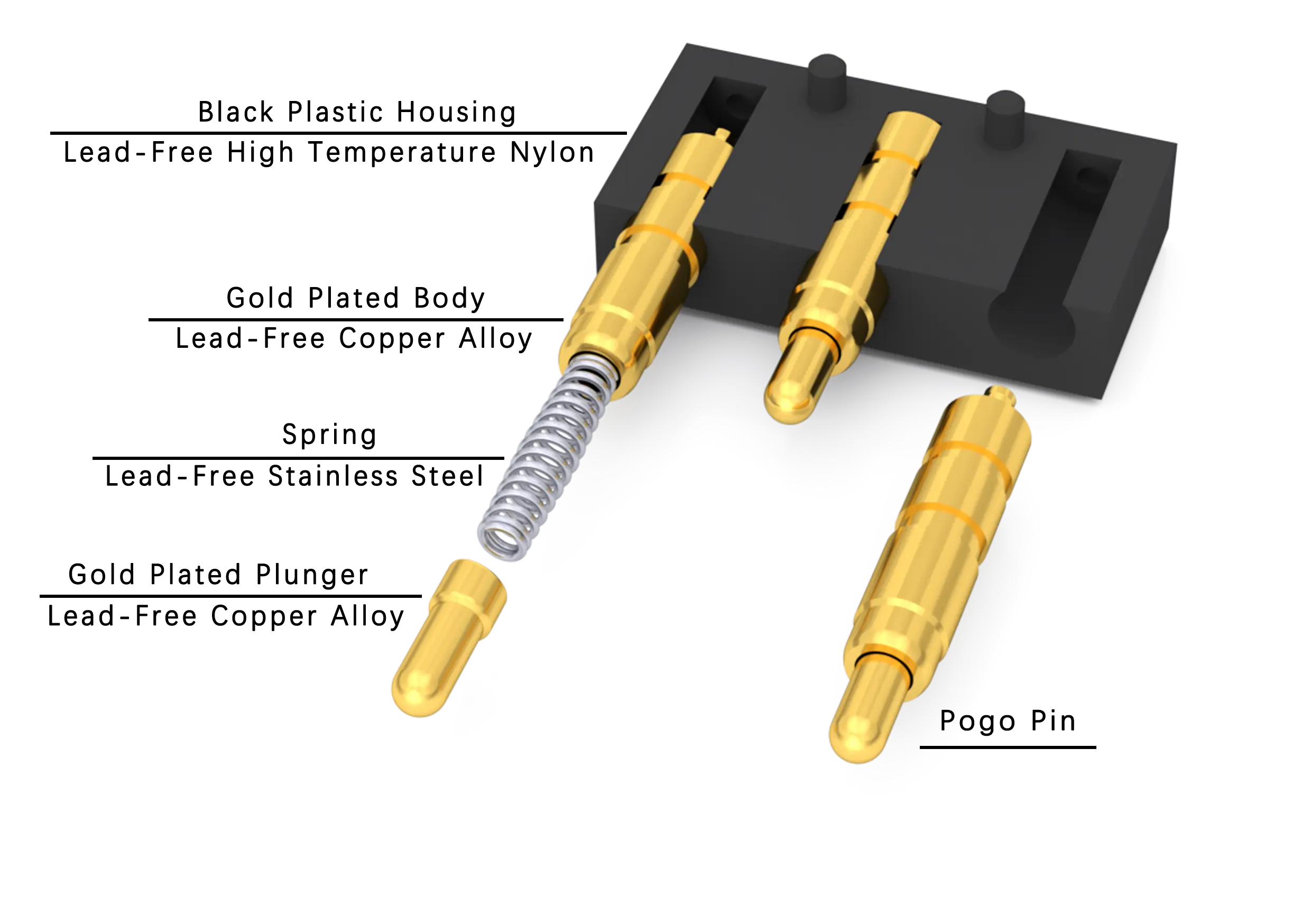

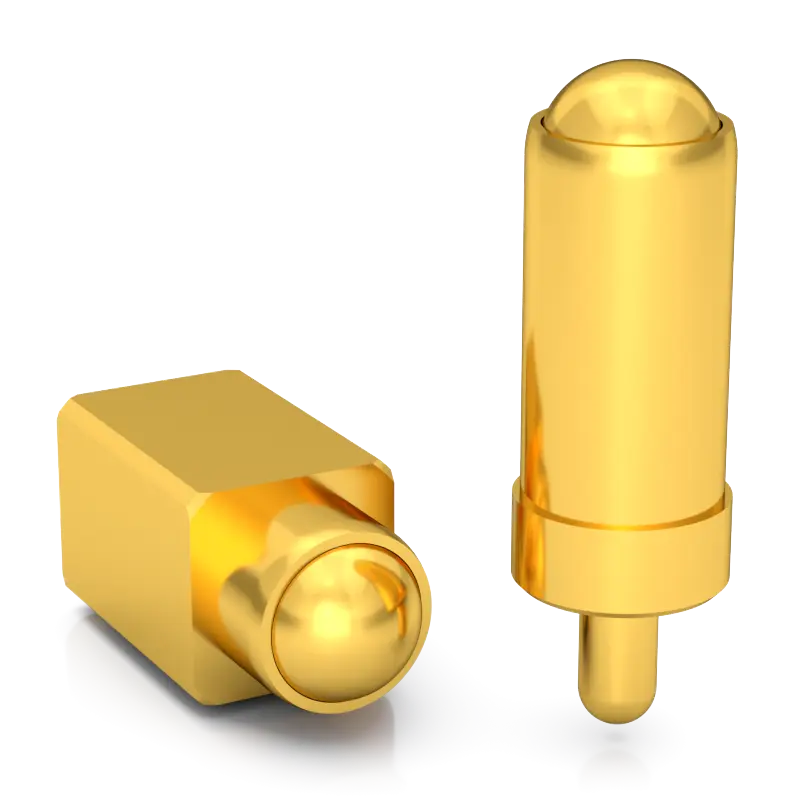

The interior of the SMD Side Contact Pogo Pin Connector adopts an inclined surface structure and built-in spring mechanism design. It is mainly composed of multiple Pogo Pins and housing, two core components, assembled through precise molds and specialized equipment. The purpose of the inclined surface structure design is to ensure that when the Pogo Pin is working, the lateral force generated by the contact between the inclined surface and the spring allows the pinhead to maintain stable contact force with the inner wall of the pin tube. This promotes the main current path through the gold-plated pinhead (Plunger) and pin tube (Body), thus achieving stable and extremely low contact resistance, maintaining stable and reliable connection even in frequent plug-ins and plug-outs

How to install smd side contact pogo pin connectors

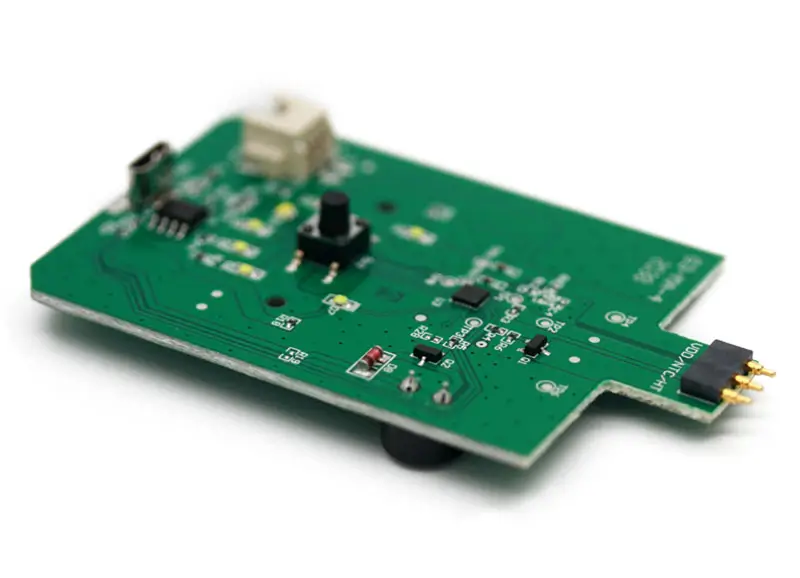

SMT automatic patch reflow soldering technology: The SMT automatic patch machine automatically mounts the smd side contact pogo pin female connector onto the PCB circuit board with printed solder paste. The solder legs are precisely inserted into the holes of the PCB circuit board, and then the solder paste is melted and solidified through the reflow soldering process, completing the fixed connection with the PCB solder pad. This process is fast, highly accurate, highly automated, significantly improving production efficiency and product quality.

smd side contact pogo pin female connector material & Parts

The SMD Side Contact Pogo Pin Connector is a type of Pogo Pin connector, a built-in spring connector manufactured based on an inclined surface structure design. It is typically composed of two core components, the Pogo Pin and the housing. Its characteristic is the side contact type, suitable for SMT automatic patch reflow soldering. It has high welding strength (more firmly welded with the PCB circuit board), very low resistance, stable and reliable connection, long lifespan, and is more durable.

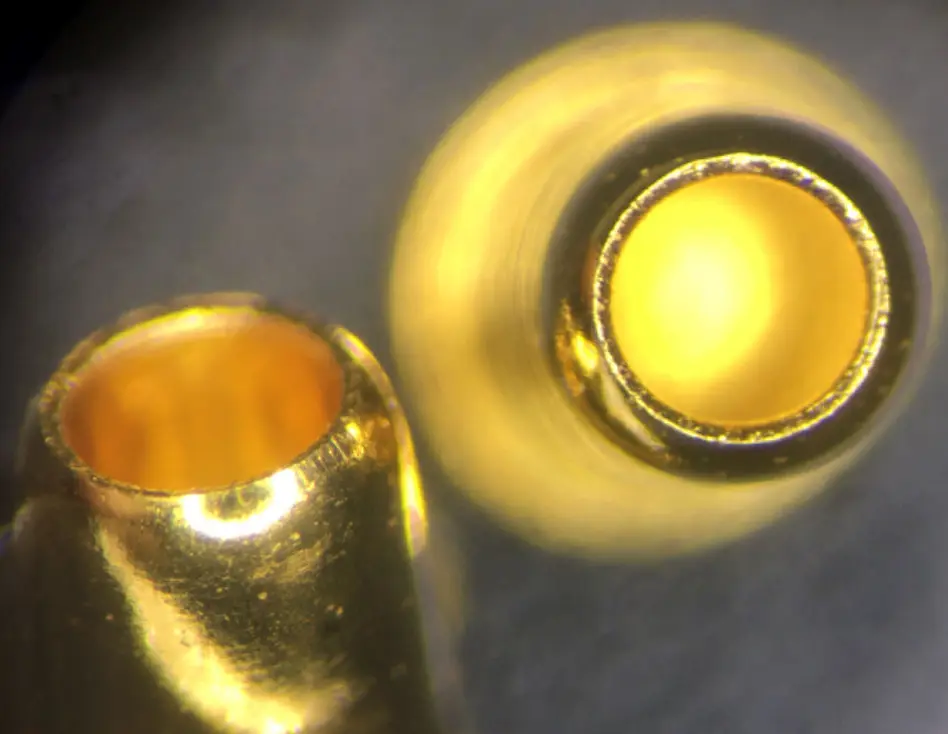

Xurui Technology

The vacuum blind hole electroplating technology is known for its superior performance, capable of quickly and accurately electroplating a layer of gold inside and outside extremely fine blind holes. This excellent electroplating process not only ensures the overall aesthetics of the metal surface but also has outstanding corrosion resistance and wear resistance. Both the inside and the outside of the hole present a bright golden color, and there will be no peeling or gold dropping issues.

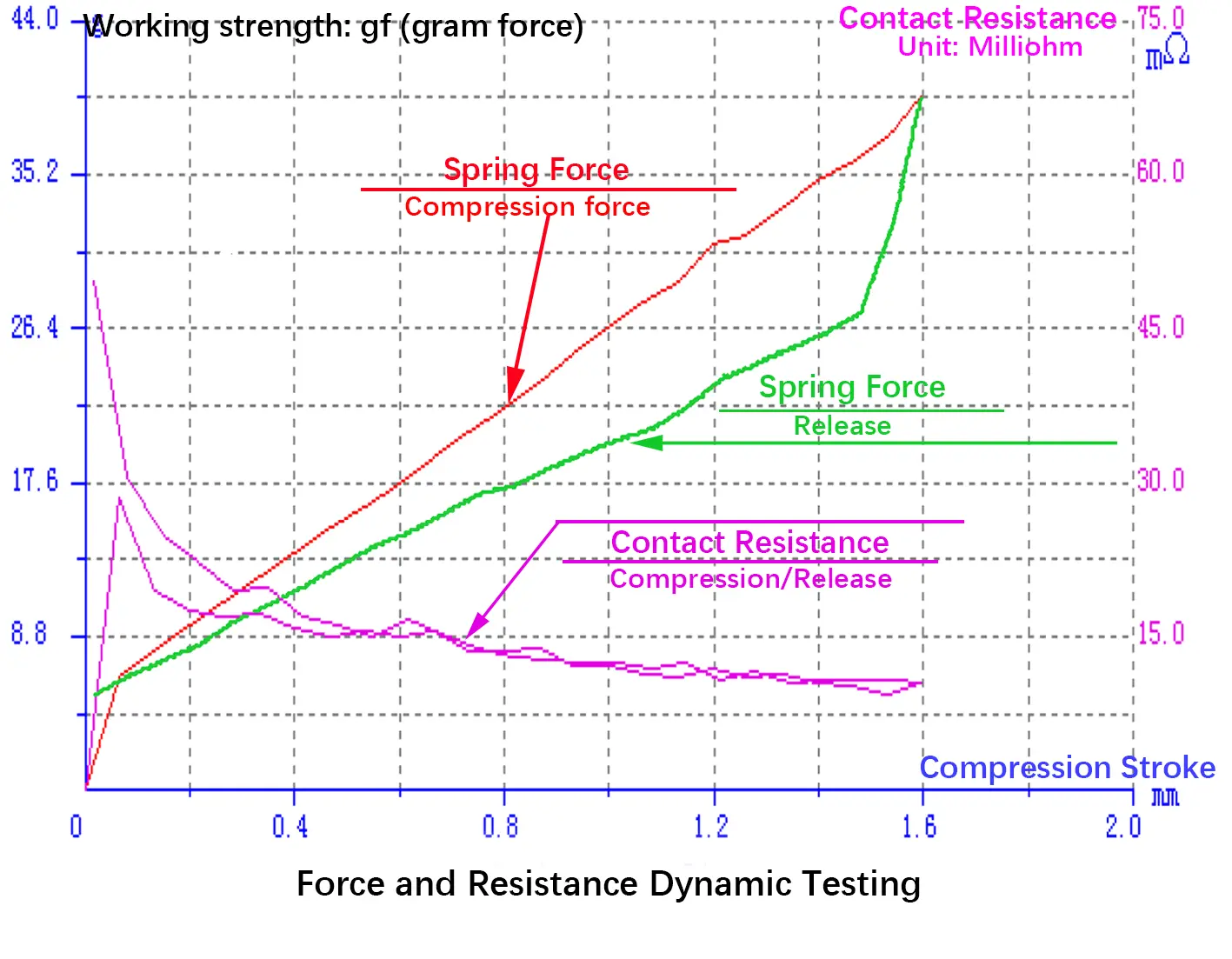

smd side contact pogo connectors contact resistance

By combining mature design concepts, high-precision processing techniques, and excellent vacuum blind hole electroplating technology, we can achieve extremely low and stable contact resistance.

XURUI

SMD Side Contact Pogo Pin Connector Technical Parameters

| Items | Details |

|---|---|

| Material | Plunger: Lead-Free Copper Alloy |

| Body: Lead-Free Copper Alloy | |

| Spring: Stainless Steel | |

| SolidPin: Lead-Free Copper Alloy | |

| Housing: Lead-Free-High Temperature Nylon | |

| Main Technical Parameters | Operating temperature: -40~+120°C(Standard) |

| Operating humidity: 20-85%RH | |

| Storage temperature: -10~+50°C | |

| Storage humidity: 20-85%RH | |

| Rating voltage: 36V AC/DC(Standard) | |

| Rating current: 2A/Pin Continuous(Standard) | |

| Contact resistance: 30 mΩ Max.(Standard) | |

| Withstanding voltage: 250V AC ,1 Minute | |

| Insulation resistance: 500 MΩ Min | |

| Durability:10,000 Cycle(Standard) | |

| Working Spring Force:70~180gf(Standard) | |

| Electroplating | Plunger: Ni Plating 1.4μm, Gold Plating 0.30μm |

| Body: Ni Plating 1.4μm, Gold Plating 0.10μm | |

| SolidPin: Ni Plating 1.4μm, Gold Plating 0.10μm | |

| Contact Type | Side Contact Type |

| Installation Method | SMT automatic placement machine+Reflow soldering |

| Plugin machine + Wave soldering | |

| Environmental Protection Standard | Comply with EU RoHS and Reach standards |

XURUI

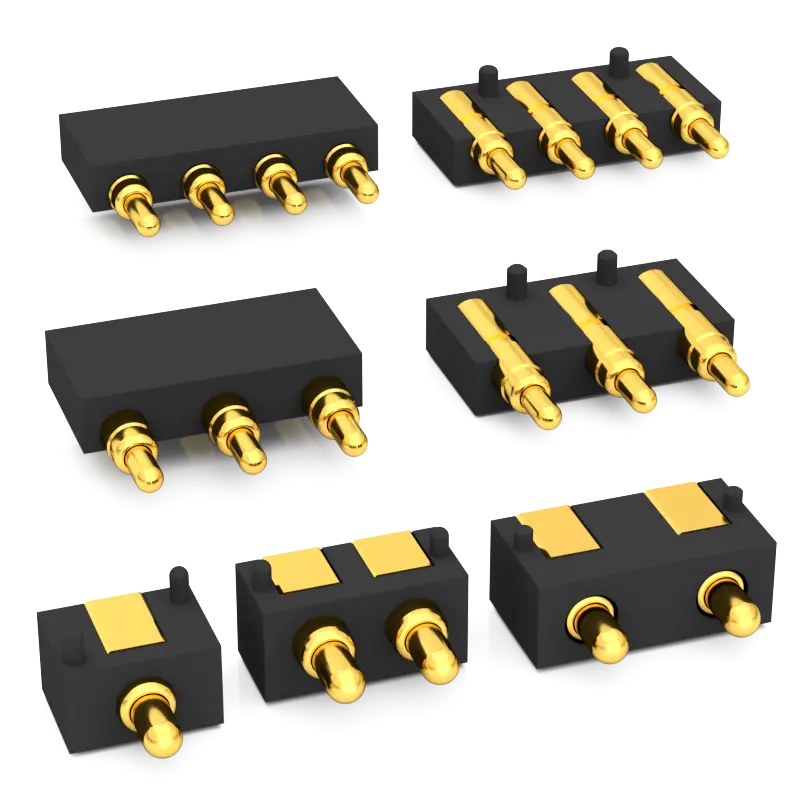

Selection Guide of SMD Side Contact Pogo Pin Connector

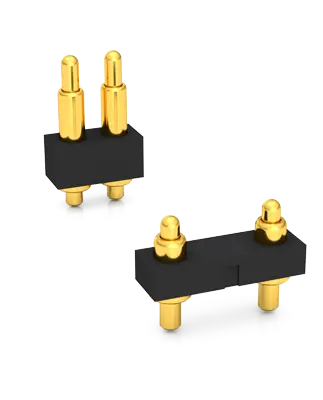

| SN | Product Image | Number Of Pins | Pitch |

|---|---|---|---|

| 1 |

|

2Pin | 2.50 |

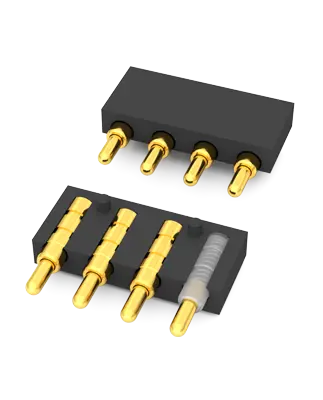

| 2 |

|

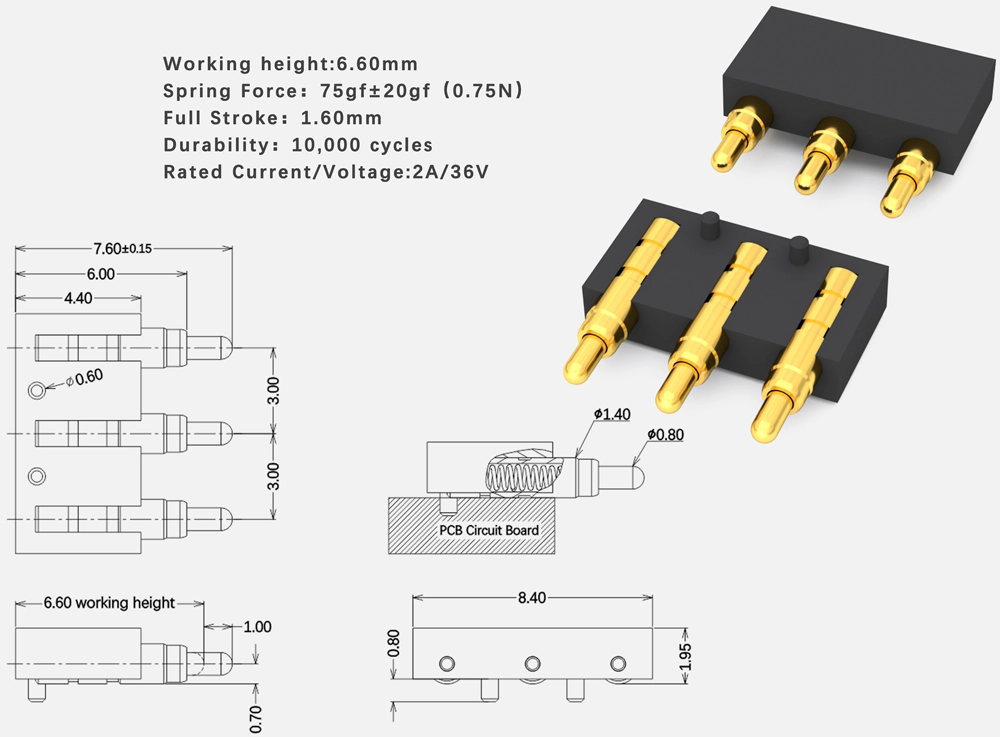

3Pin | 3.00 |

| 3 |

|

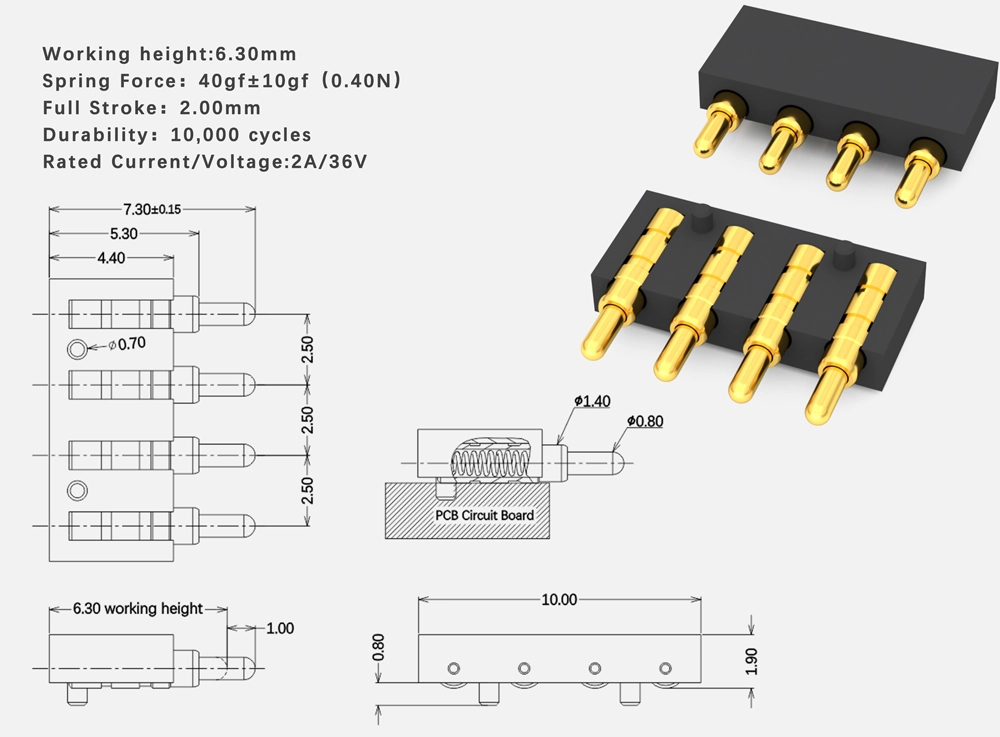

4Pin | 2.50 |

xurui

SMD Side Contact Pogo Pin Connector Standard Product

Pop Up Your Dreams

XURUI offers 24/7 ongoing global support, ensuring we’re there for clients whenever needed.

xurui

Related Pogo Pins

xurui

Pogo Pin Guide

How to solve the problem of poor contact of Pogo Pin

In the field of modern electronic manufacturing, Pogo Pin (spring pin) is an important connector component, widely used in test

What are the technical innovations of Pogo Pin connectors?

The development of Pogo Pin connector is not limited to product innovation, but also includes the improvement of manufacturing process

Application and value of pogo pin in OWS headphones

OWS headphones Pogo pin magnetic charging technology is undoubtedly an innovative breakthrough in the field of modern wireless headphones. This